Shrimp from the mountains: sounds crazy, but it's real!

The initial situation

Sometimes the best stories are written by chance. This is also the case with White Panther shrimp production in Rottenmann, Styria. The idea to expand the business operations to include a shrimp farm and a wood gas power plant, which supplies the farm with heat, came from founder and idea generator Ingrid Flick. In addition to green electricity, the wood gas plant generates waste heat, the most important purpose of which is now to continuously heat the tanks in which the mountain prawns swim. Construction of the indoor shrimp farm began in 2017 and the precious crustaceans have been bred there regionally and sustainably since 2019.

Rearing & technology

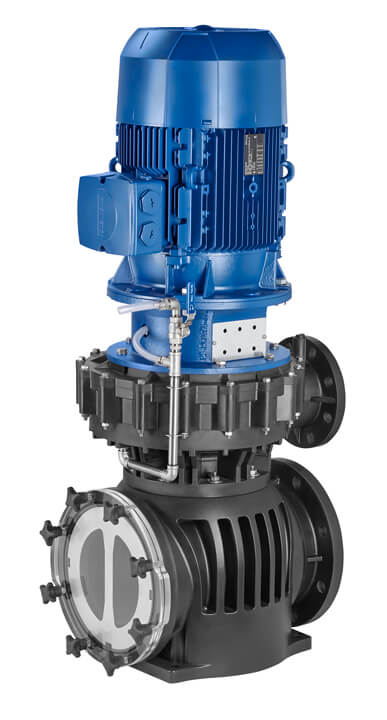

Depending on body weight, each mother lays between 200,000 and 300,000 eggs. After 24 hours, egg development is complete and the so-called naupilus larvae hatch. Over several stages, the finished postlarvae develop within 2 weeks. Initially, the microscopically small animals are kept in special tanks and fed with home-grown algae. After 4 weeks, the postlarvae are transferred to the rearing hall, the so-called grow-out. In this grow-out phase, the postlarvae are first placed in nursery tanks. For the next 5 to 6 weeks, the young mountain prawns are only fed with special rearing food. The animals are then transferred to larger tanks where they grow to around 30 grams in around 4 months. The water in the grow-out tanks is mixed with a special marine and mineral mixture. Food residues, feces and skin residues are collected mechanically. With the help of microorganisms, the water is biologically filtered and prepared for the mountain prawns. At the end, the purified water flows back into the tanks. The right technology plays a decisive role in the optimal development of the Styrian mountain prawns: a total of 9 BADU Block Multi Mar - 6 BADU Block Multi Mar 125/250 and 3 BADU Block Multi Mar 100/250 - are used as saltwater circulation pumps between the filter system and the rearing tanks and circulate a volume of water of up to 200 m³/h. They ensure that the water is circulated throughout the entire system. They ensure constant and optimum water quality in the tanks throughout the entire system. The pumps, which have been specially developed for aquaculture applications and are made of high-performance engineering plastic, are corrosion-resistant and are characterized above all by low power consumption, high efficiency and extremely quiet running.

For our shrimp farming system, we need robust and compact pumps that are suitable for use in aquaculture applications. The BADU Block Multi Mar pumps from SPECK have all these features - and all this at an excellent price-performance ratio.<<

Ecological sustainability

From the outset, the focus of the project was on a holistic concept of ecological sustainability - from the company's own forest and spring water to a self-sufficient energy and heat supply via the wood gas power plant, which generates electricity and heat for production from wood from the company's own forestry operations. All growth stages - from the egg to the adult animal - take place in Rottenmann, Austria. Thanks to the company's own hatchery, the larvae hatch locally and are not flown in from overseas. By rearing them close to the end customer, the exploitation of the oceans and the environmental impact of huge fishing fleets and long transportation routes are prevented. The food, such as the algae for the young animals, is also grown in Rottenmann. Special insulated packaging ensures optimum cooling during delivery. Instead of polystyrene, White Panther Produktion GmbH uses compostable straw. This means that the prawns do not have to be frozen, but can be delivered fresh within 24 hours of harvesting.

The end product

The aquaculture facility in Rottenmann is designed for an annual production of around 60 tons, making it one of the largest in Europe. The "White Tiger Shrimp" (Litopenaeus Vannamei) and the lesser-known but globally rare delicacy "Blue Shrimp" (Litopenaeus Stylirostris) are cultivated there. The latter is considered difficult to cultivate and only a state-of-the-art facility makes it possible to carry out the complex steps involved in breeding. The changes in natural living conditions depending on the shrimp's stage of development are taken into account: The parent animals live and spawn in deeper marine areas, while the juveniles are found near the coast. These different life stages are faithfully reproduced in the aquaculture facility. The indoor climate, salt content, nutrients, pH value, oxygen content, lighting and temperature are harmoniously modeled on nature from tank to tank. Only in this way can the mountain prawns be reared healthily and without the need for antibiotics, hormones or other chemicals. Thanks to their high quality and freshness, the mountain prawns farmed in Styria can be enjoyed freshly harvested on your plate. As most of the flavor is found in the head part, the prawns are sold with head and shell (HOSO - head-on shell-on) locally via the Gebirgsgarnelenshop in Rottenmann, the company's own online store, selected partners or in top restaurants. They are delivered in sustainable packaging, chilled and not frozen. In Europe, the "blue shrimp" is only sold fresh - not frozen - by White Panther.

White Panther Production GmbH

In 2017, a sustainable indoor aquaculture facility was built in Rottenmann, Styria, Austria, with the mission of breeding shrimp far away from the ocean. Eva Keferböck, Stefan Weiser and Ludwig Germann are the managing directors of White Panther Produktion GmbH and are responsible for the sustainable shrimp farm. With its Styrian mountain prawns, the company provides a local, sustainable and fresh alternative to frozen products from overseas. Since 2019, the company has also been producing postlarvae for its own breeding and for sale to other shrimp farms in its own hatchery.